Formula and Baja laser frame coping

Over the last 3 months we have been working hard on offering you full frame laser coping. We can not thank UTA Formula Racing Team enough for all the support and help they have given to us throughout this process.

WHAT IS LASER CUTTING?

Laser cutting is a technology that has been in use since the 1960s. Basically, it involves using a laser to cut material. It is an automated computerized process that points a high-power laser at material which causes it to melt, burn or vaporize away. It leaves a high-quality surface finish that is free of burrs. Lasers can be used to cut all types of materials including wood, plastics and metals. They can cut flat materials as well as tubular shaped. Lasers can provide endless intricate shapes and designs that cannot be achieved with other cutting methods.

ADVANTAGES OF LASER TECHNOLOGY

Laser technology is a quality enhancing manufacturing process that offers more possibilities than virtually any other traditional machining process. It can eliminate the need for machining on many jobs enabling customers to reduce their manufacturing costs. Advantages include:

- Enhanced precision

- Better edge quality

- Ability to cut complex shapes without the need for tooling

- Faster speed

- Reduced chance of material warping

- Ability to cut materials that are impossible to cut with more traditional methods

The Laser Coping Process: The latest Adige LT fibers is one of the fastest laser tube cutting machines on the market today. This allows us to cut very complex products such as chassis tubes for the racing industry in a matter of seconds. Our laser machines often provide the most effective process for cutting plate, sheet, or tubing metal for metal fabrication, including carbon steel, stainless steel, aluminum, and many other alloys.

Cost Efficient and Ultimate Flexibility: Our laser cutting equipment includes long bed, 4-axis lasers with power ranging from 2000 to 3200 watts to deliver cost efficient flexibility. Each machine is able to chuck up to 6“ diameter. The 2000 watt fiber machines cut thin wall tubing up to 1/4“ with better accuracy, no burrs and a smooth finish while maintaining a competitive cost in comparison to other mechanical processes. The 3000 and 3200 watt CO2 lasers allow us to cut material up to 24” in diameter and 5/8” thick.

Cutting Large Volumes of Tubular Products: Our vendor has automatic production tube cutting cells with 3200 watts of cutting power. Each machine is equipped with fully automatic tube feeders up to 30 feet, minimizing the challenges and cost of producing large volumes of tubular products. These machines offer the ultimate in power, accuracy and cost reductions as well as tolerances of +/- 0.005“ in profiling or cut-to-length.

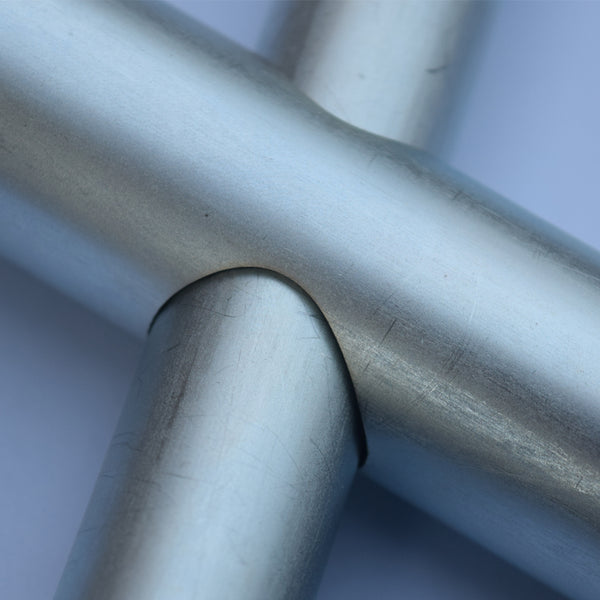

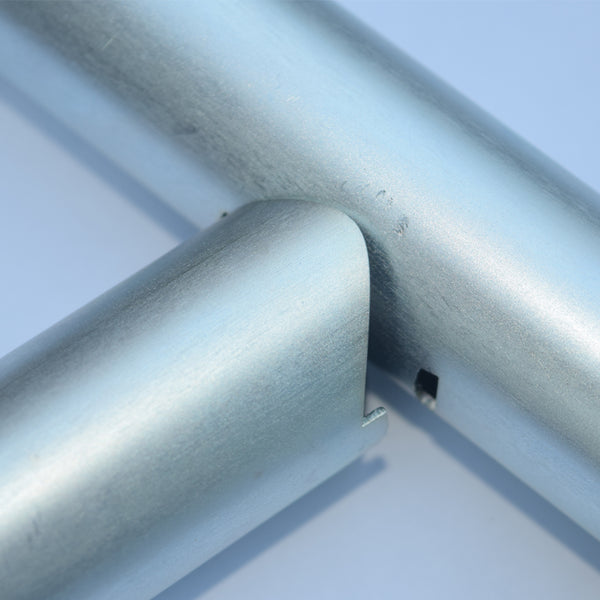

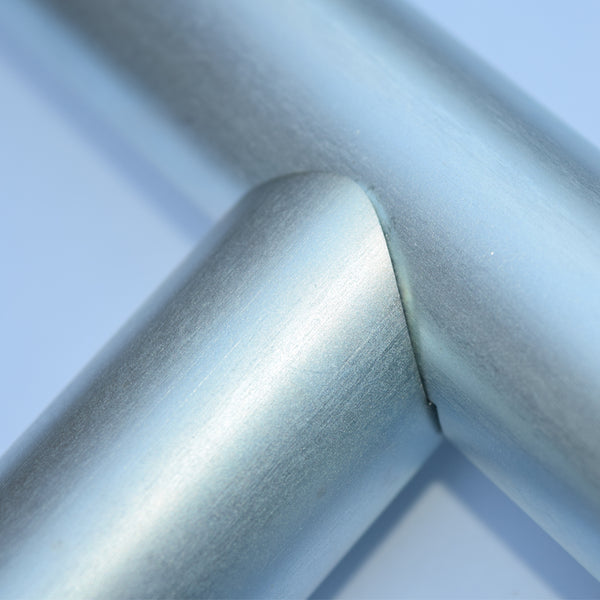

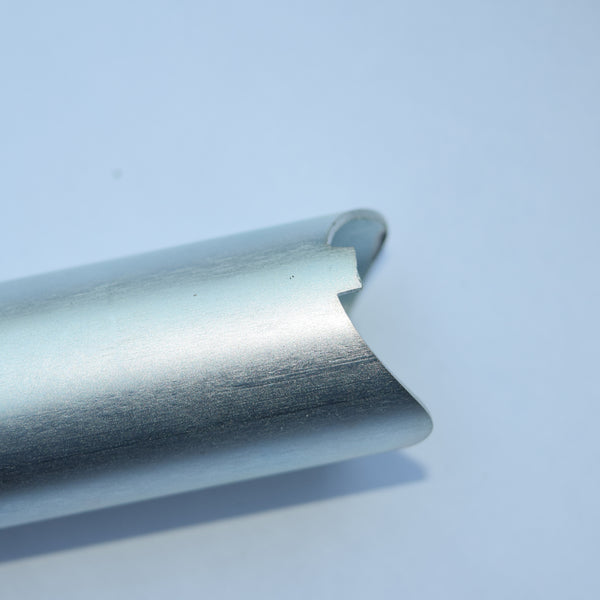

Check out some of the example cuts bellow! The tubes in the pictures below are 4130 Chrome Molly tubing that has been Zinc plated for demo purposes only. The Zinc plating is just to keep it from rusting when we take the sample laser coped tubes to races and tradeshows.

Round Thru Coping:

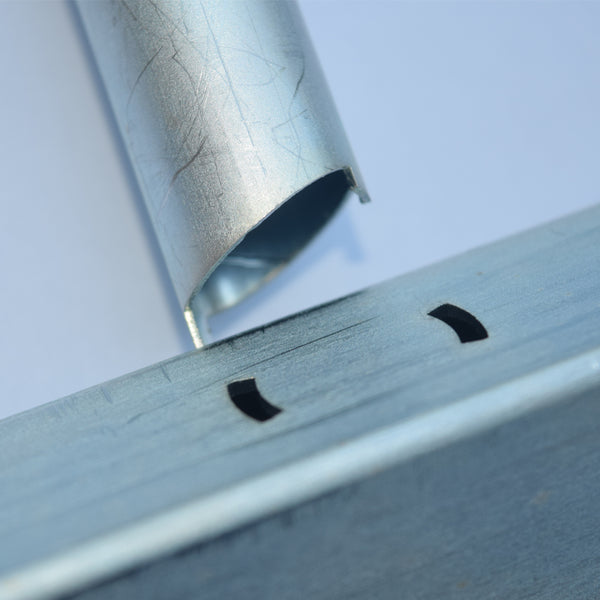

Round Coping With Alignment Pins:

Round Coping With Alignment Pins:

Round Coping With Alignment Pins:

Round Coping Alignment Pin:

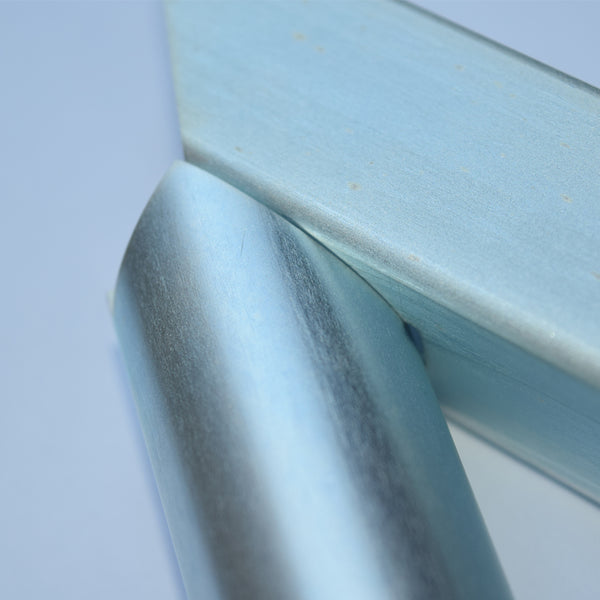

Round To Square Coping With Alignment Pins:

Round To Square Coping With Alignment Pins:

Round To Square Coping With Alignment Pins:

Round To Square Coping With Alignment Pins:

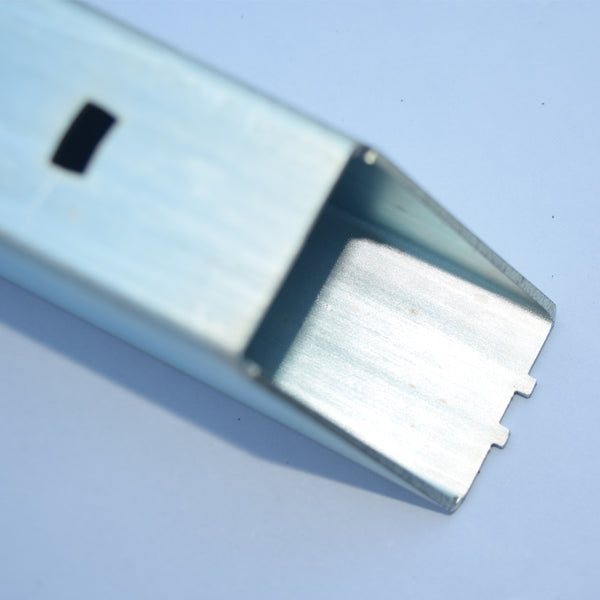

Square Coping Alignment Pins:

Our Goals:

Our goal at FSAEparts is to offer you the best discounts we can. In this case we have set up a partnership for this laser coping process. We have had two sample frames made and a few sample displays to prove out the process. We now have a streamline process which offers great prices and outstanding quality.

Breakdown:

**Prices will vary due to the complexity of the frame and the amount of tubes. This estimated figure is based off what we considered to be a more advanced steel space frame.****

- One frame design sent to us at any given time

- Estimated cost of $2,200 USD (This includes material and all laser coping)

- Ten different frame designs all sent in by a certain date

- Estimated cost of $1,300 USD (This includes material and all laser coping)

The more teams that submit designs the cheaper the cost. The reason for this is that the laser coping machine takes some time to set up and change out heads for different diameters. The laser machine also has automatic feed capabilities. So say you have 10 teams all using some 1"OD x 0.035"wall for several tubes. The machine would cut all those tubes automatically then sort them out to the proper team, thus driving the cost down.

We will be making a poll on what tube sizes your team uses. Please Please Please keep an eye out for the poll and fill it out when you get it. This will allow for use to offer a list of "standard" sizes to design your car space frame with which will make the final cost even cheaper.

Our ultimate goal is to be able to laser cope your frame cheaper than you can purchase the material! So spread the word and leave your thoughts and comments bellow.

100 Responses

شركة مكافحة حشرات بالدمام

شركة مكافحة حشرات بالدمام وكذلك شركة كشف تسربات المياه بالدمام وتنظيف خزانات وتنظيف الموكيت والسجاد والكنب والشقق والمنازل بالدمام وتنظيف الخزانات بالدمام وتنظيف المساجد بالدمام شركة تنظيف بالدمام تنظيف المسابح بالدمام

https://jumperads.com/dammam/anti-insects-company-dammam.html شركة مكافحة حشرات بالدمام

https://jumperads.com/dammam/water-leaks-detection-company-dammam.html شركة كشف تسربات بالدمام

https://jumperads.com/dammam/dammam-company-surfaces.html شركة عزل اسطح بالدمام

https://jumperads.com/dammam/dammam-company-sewage.html شركة تسليك مجاري بالدمام

https://jumperads.com/dammam/dammam-cleaning-company-sofa.html شركة تنظيف كنب بالدمام

https://jumperads.com/dammam/dammam-cleaning-company-mosques.html شركة تنظيف مساجد بالدمام

https://jumperads.com/dammam/dammam-cleaning-company-Carpet.html شركة تنظيف سجاد بالدمام

https://jumperads.com/dammam/dammam-cleaning-company-tanks.html شركة تنظيف خزانات بالدمام

https://jumperads.com/dammam/dammam-cleaning-company-swimming-bath.html شركة تنظيف وصيانة مسابح بالدمام

https://jumperads.com/dammam/dammam-cleaning-company-Furniture.html شركة تنظيف الاثاث بالدمام

https://jumperads.com/dammam/dammam-cleaning-company-home.html شركة تنظيف شقق بالدمام

https://jumperads.com/dammam/dammam-cleaning-company-Carpets.html شركة تنظيف موكيت بالدمام

https://jumperads.com/dammam/dammam-cleaning-company.html شركة تنظيف مجالس بالدمام

https://jumperads.com/dammam/dammam-cleaning-company-house.html شركة تنظيف منازل بالدمام

https://jumperads.com/dammam/dammam-cleaning-company-curtains.html شركة تنظيف ستائر بالدمام

https://jumperads.com/dammam/dammam-cleaning-company-Villas.html شركة تنظيف فلل بالدمام

https://jumperads.com/dammam/dammam-company-tile.html شركة جلي بلاط بالدمام

شركات نقل عفش واثاث بجدة

https://emc-mee.com/blog.html شركات نقل العفش

اهم شركات كشف تسربات المياه بالدمام كذلك معرض اهم شركة مكافحة حشرات بالدمام والخبر والجبيل والخبر والاحساء والقطيف كذكل شركة تنظيف خزانات بجدة وتنظيف بجدة ومكافحة الحشرات بالخبر وكشف تسربات المياه بالجبيل والقطيف والخبر والدمام

https://emc-mee.com/cleaning-company-yanbu.html شركة تنظيف بينبع

https://emc-mee.com/blog.html شركة نقل عفش

اهم شركات مكافحة حشرات بالخبر كذلك معرض اهم شركة مكافحة حشرات بالدمام والخبر والجبيل والخبر والاحساء والقطيف كذلك شركة رش حشرات بالدمام ومكافحة الحشرات بالخبر

https://emc-mee.com/anti-insects-company-dammam.html شركة مكافحة حشرات بالدمام

شركة تنظيف خزانات بجدة الجوهرة من افضل شركات تنظيف الخزانات بجدة حيث ان تنظيف خزانات بجدة يحتاج الى مهارة فى كيفية غسيل وتنظيف الخزانات الكبيرة والصغيرة بجدة على ايدى متخصصين فى تنظيف الخزانات بجدة

https://emc-mee.com/tanks-cleaning-company-jeddah.html شركة تنظيف خزانات بجدة

https://emc-mee.com/water-leaks-detection-isolate-company-dammam.html شركة كشف تسربات المياه بالدمام

https://emc-mee.com/ شركة الفا لنقل عفش واثاث

https://emc-mee.com/transfer-furniture-jeddah.html شركة نقل عفش بجدة

https://emc-mee.com/transfer-furniture-almadina-almonawara.html شركة نقل عفش بالمدينة المنورة

https://emc-mee.com/movers-in-riyadh-company.html شركة نقل اثاث بالرياض

https://emc-mee.com/transfer-furniture-dammam.html شركة نقل عفش بالدمام

https://emc-mee.com/transfer-furniture-taif.html شركة نقل عفش بالطائف

https://emc-mee.com/transfer-furniture-mecca.html شركة نقل عفش بمكة

https://emc-mee.com/transfer-furniture-yanbu.html شركة نقل عفش بينبع

https://emc-mee.com/transfer-furniture-alkharj.html شركة نقل عفش بالخرج

https://emc-mee.com/transfer-furniture-buraydah.html شركة نقل عفش ببريدة

https://emc-mee.com/transfer-furniture-khamis-mushait.html شركة نقل عفش بخميس مشيط

https://emc-mee.com/transfer-furniture-qassim.html شركة نقل عفش بالقصيم

https://emc-mee.com/transfer-furniture-tabuk.html شركة نقل عفش بتبوك

https://emc-mee.com/transfer-furniture-abha.html شركة نقل عفش بابها

https://emc-mee.com/transfer-furniture-najran.html شركة نقل عفش بنجران

https://emc-mee.com/transfer-furniture-hail.html شركة نقل عفش بحائل

https://emc-mee.com/transfer-furniture-dhahran.html شركة نقل عفش بالظهران

https://emc-mee.com/transfer-furniture-kuwait.html شركة نقل عفش بالكويت

https://emc-mee.com/price-transfer-furniture-in-khamis-mushit.html اسعار شركات نقل عفش بخميس مشيط

https://emc-mee.com/numbers-company-transfer-furniture-in-khamis-mushit.html ارقام شركات نقل عفش بخميس مشيط

https://emc-mee.com/new-company-transfer-furniture-in-khamis-mushit.html شركة نقل عفش بخميس مشيط جديدة

https://emc-mee.com/transfer-furniture-from-khamis-to-riyadh.html شركة نقل عفش من خميس مشيط الي الرياض

https://emc-mee.com/transfer-furniture-from-khamis-mushait-to-mecca.html شركة نقل عفش من خميس مشيط الي مكة

https://emc-mee.com/transfer-furniture-from-khamis-mushait-to-jeddah.html شركة نقل عفش من خميس مشيط الي جدة

https://emc-mee.com/transfer-furniture-from-khamis-mushait-to-medina.html شركة نقل عفش من خميس مشيط الي المدينة المنورة

https://emc-mee.com/best-10-company-transfer-furniture-khamis-mushait.html افضل 10 شركات نقل عفش بخميس مشيط

https://emc-mee.com/%D8%B4%D8%B1%D9%83%D9%87-%D9%86%D9%82%D9%84-%D8%B9%D9%81%D8%B4-%D8%A8%D8%AC%D8%AF%D9%87.html

https://emc-mee.com/%D8%B4%D8%B1%D9%83%D8%A9-%D9%86%D9%82%D9%84-%D8%A7%D8%AB%D8%A7%D8%AB-%D8%A8%D8%AC%D8%AF%D9%87.html

شركات نقل عفش واثاث بجدة

شركات نقل عفش واثاث بجدة

شركات نقل عفش بالطائف

اسعار وارقام شركات نقل العفش بالمدينة المنورة

دينا نقل عفش جدة ,افضل دينا

ارخص شركه نقل عفش بجده

دليل شركات نقل العفش بجدة

شركة نقل عفش برابغ ,15 عام خبرة

شركات نقل عفش واثاث بالباحه

وسائل نقل العفش بخميس مشيط

شركة كيان لنقل العفش

شركة كيان لنقل العفش بالرياض والمدينة المنورة وجدة ومكة والطائف والدمام تقديم لكم دليل كامل لشركات نقل العفش بالمملكة العربية السعودية

https://mycanadafitness.com/ شركة كيان لنقل العفش

https://mycanadafitness.com/forum.html منتدي نقل العفش

https://mycanadafitness.com/movingfurnitureriyadh.html شركة نقل اثاث بالرياض

https://mycanadafitness.com/movingfurniturejaddah.html شركة نقل اثاث بجدة

https://mycanadafitness.com/movingfurnituremecca.html شركة نقل اثاث بمكة

https://mycanadafitness.com/movingfurnituretaif.html شركة نقل اثاث بالطائف

https://mycanadafitness.com/movingfurnituremadina.html شركة نقل اثاث بالمدينة المنورة

https://mycanadafitness.com/movingfurnituredammam.html شركة نقل اثاث بالدمام

https://mycanadafitness.com/movingfurniturekhobar.html شركة نقل اثاث بالخبر

https://mycanadafitness.com/movingfurnituredhahran.html شركة نقل اثاث بالظهران

https://mycanadafitness.com/movingfurniturejubail.html شركة نقل اثاث بالجبيل

https://mycanadafitness.com/movingfurnitureqatif.html شركة نقل اثاث بالقطيف

https://mycanadafitness.com/movingfurnitureahsa.html شركة نقل اثاث بالاحساء

https://mycanadafitness.com/movingfurniturekharj.html شركة نقل اثاث بالخرج

https://mycanadafitness.com/movingfurniturekhamismushit.html شركة نقل اثاث بخميس مشيط

https://mycanadafitness.com/movingfurnitureabha.html شركة نقل اثاث بابها

https://mycanadafitness.com/movingfurniturenajran.html شركة نقل اثاث بنجران

https://mycanadafitness.com/movingfurniturejazan.html شركة نقل اثاث بجازان

https://mycanadafitness.com/movingfurnitureasir.html شركة نقل اثاث بعسير

https://mycanadafitness.com/movingfurniturehail.html شركة نقل اثاث بحائل

https://mycanadafitness.com/movingfurnitureqassim.html شركة نقل عفش بالقصيم

https://mycanadafitness.com/movingfurnitureyanbu.html شركة نقل اثاث بينبع

https://mycanadafitness.com/movingfurnitureburaidah.html شركة نقل عفش ببريدة

https://mycanadafitness.com/movingfurniturehafralbatin.html شركة نقل عفش بحفر الباطن

https://mycanadafitness.com/movingfurniturerabigh.html شركة نقل عفش برابغ

https://mycanadafitness.com/movingfurnituretabuk.html شركة نقل عفش بتبوك

https://mycanadafitness.com/movingfurnitureasfan.html شركة نقل عفش بعسفان

https://mycanadafitness.com/movingfurnituresharora.html شركة نقل عفش بشرورة

https://mycanadafitness.com/companis-moving-riyadh.html شركات نقل العفش بالرياض

https://mycanadafitness.com/cars-moving-riyadh.html سيارات نقل العفش بالرياض

https://mycanadafitness.com/company-number-moving-riyadh.html ارقام شركات نقل العفش بالرياض

https://mycanadafitness.com/company-moving-jeddah.html شركات نقل العفش بجدة

https://mycanadafitness.com/price-moving-jeddah.html اسعار نقل العفش بجدة

https://mycanadafitness.com/company-moving-mecca.html شركات نقل العفش بمكة

شركة سكاي نقل العفش

شركة سكاي لخدمات نقل العفش والاثاث بالمنطقة العربية السعودية نحن نوفر خدمات نقل اثاث بالرياض ونقل عفش بالمدينة المنورة ونقل عفش بمكة ونقل عفش بالطائف نحن نقدم افضل نقل اثاث بخميس مشيط ونقل عفش بجدة

https://treeads.net/ شركة سكاي نقل العفش

https://treeads.net/blog.html مدونة لنقل العفش

https://treeads.net/movers-mecca.html شركة نقل عفش بمكة

https://treeads.net/movers-riyadh-company.html شركة نقل عفش بالرياض

https://treeads.net/all-movers-madina.html شركة نقل عفش بالمدينة المنورة

https://treeads.net/movers-jeddah-company.html شركة نقل عفش بجدة

https://treeads.net/movers-taif.html شركة نقل عفش بالطائف

https://treeads.net/movers-dammam-company.html شركة نقل عفش بالدمام

https://treeads.net/movers-qatif.html شركة نقل عفش بالقطيف

https://treeads.net/movers-jubail.html شركة نقل عفش بالجبيل

https://treeads.net/movers-khobar.html شركة نقل عفش بالخبر

https://treeads.net/movers-ahsa.html شركة نقل عفش بالاحساء

https://treeads.net/movers-kharj.html شركة نقل عفش بالخرج

https://treeads.net/movers-khamis-mushait.html شركة نقل عفش بخميس مشيط

https://treeads.net/movers-abha.html شركة نقل عفش بابها

https://treeads.net/movers-qassim.html شركة نقل عفش بالقصيم

https://treeads.net/movers-yanbu.html شركة نقل عفش بينبع

https://treeads.net/movers-najran.html شركة نقل عفش بنجران

https://treeads.net/movers-hail.html شركة نقل عفش بحائل

https://treeads.net/movers-buraydah.html شركة نقل عفش ببريدة

https://treeads.net/movers-tabuk.html شركة نقل عفش بتبوك

https://treeads.net/movers-dhahran.html شركة نقل عفش بالظهران

https://treeads.net/movers-rabigh.html شركة نقل عفش برابغ

https://treeads.net/movers-baaha.html شركة نقل عفش بالباحه

https://treeads.net/movers-asseer.html شركة نقل عفش بعسير

https://treeads.net/movers-mgmaa.html شركة نقل عفش بالمجمعة

https://treeads.net/movers-sharora.html شركة نقل عفش بشرورة

https://treeads.net/how-movers-furniture-yanbu.html كيفية نقل العفش بينبع

https://treeads.net/price-movers-furniture-yanbu.html اسعار نقل عفش بينبع

https://treeads.net/find-company-transfer-furniture-yanbu.html البحث عن شركات نقل العفش بينبع

https://treeads.net/transfer-furniture-khamis-mushit.html شركات نقل العفش بخميس مشيط

https://treeads.net/how-transfer-furniture-khamis-mushit.html كيفية نقل العفش بخميس مشيط

https://treeads.net/price-transfer-furniture-khamis-mushit.html اسعار نقل عفش بخميس مشيط

https://treeads.net/%D8%B4%D8%B1%D9%83%D8%A9-%D8%AC%D9%84%D9%8A-%D8%A8%D9%84%D8%A7%D8%B7-%D8%A8%D8%AC%D8%AF%D8%A9.html شركة جلي بلاط بجدة

https://treeads.net/%D8%B4%D8%B1%D9%83%D8%A9-%D8%AA%D9%86%D8%B8%D9%8A%D9%81-%D9%81%D9%84%D9%84-%D8%A8%D8%AC%D8%AF%D8%A9.html تنظيف فلل بجدة

https://treeads.net/company-transfer-furniture-jazan.html شركة نقل عفش بجازان

https://treeads.net/best-company-cleaning-jeddah-2020.html افضل شركة تنظيف بجدة

شركة نقل عفش بمكة

https://sites.google.com/view/movers-riyadh/

https://sites.google.com/view/movers-riyadh/movers-mecca

https://sites.google.com/view/movers-riyadh/home

https://sites.google.com/view/movers-riyadh/movers-jedaah-elhamdniah

https://sites.google.com/view/movers-riyadh/movers-yanbu

https://sites.google.com/view/movers-riyadh/movers-najran

https://sites.google.com/view/movers-riyadh/movers-Jizan

https://sites.google.com/view/movers-riyadh/jazan

https://sites.google.com/view/movers-riyadh/taif

https://sites.google.com/view/movers-riyadh/moversjeddah

https://sites.google.com/view/movers-riyadh/movers-abha

https://sites.google.com/view/movers-riyadh/movers-elahsa

https://sites.google.com/view/movers-riyadh/movers-elkhobar

https://sites.google.com/view/movers-riyadh/movers-elkharj

https://sites.google.com/view/movers-riyadh/movers-elmadina-elmnowara

https://sites.google.com/view/movers-riyadh/movers-eljubail

https://sites.google.com/view/movers-riyadh/movers-elqassim

https://sites.google.com/view/movers-riyadh/movers-hafrelbatin

https://sites.google.com/view/movers-riyadh/movers-elbaha

https://sites.google.com/view/movers-riyadh/movers-jeddah

https://sites.google.com/view/movers-riyadh/movers-dammam

https://sites.google.com/view/movers-riyadh/movers-taif

https://sites.google.com/view/movers-riyadh/movers-burydah

https://sites.google.com/view/movers-riyadh/movers-tabuk

https://sites.google.com/view/movers-riyadh/movers-hail

https://sites.google.com/view/movers-riyadh/movers-khamis-mushait

https://sites.google.com/view/movers-riyadh/movers-rabigh

https://sites.google.com/view/movers-riyadh/madina

https://sites.google.com/view/movers-riyadh/mecca

https://sites.google.com/view/movers-riyadh/dammam

https://sites.google.com/view/movers-riyadh/jeddah

https://sites.google.com/view/movers-riyadh/ahsa

https://sites.google.com/view/movers-riyadh/cleaning-mecca

온라인카지노

https://rb.gy/mixjhy

안전 카지노사이트_https://betop24.com/

온라인카지노 추천_https://betop24.com/

바카라사이트 추천_https://betop24.com/

파라오카지노_https://betop24.com/pharaoh-casino/

쿨카지노_https://betop24.com/cool-casino/

뉴헤븐카지노_https://betop24.com/nhcasino/

솔카지노_https://betop24.com/solcasino/

펀카지노_https://betop24.com/fun-casino/

헤라카지노_https://betop24.com/hera-casino/

https://wp.me/peP4kL-37

https://bit.ly/3rlMEof

https://adamscottybest.wordpress.com/2023/07/09/%eb%b0%94%ec%b9%b4%eb%9d%bc%ec%82%ac%ec%9d%b4%ed%8a%b8-%ec%b6%94%ec%b2%9c/

https://wordpress.com/read/feeds/142272460

https://wordpress.com/read/feeds/142272460/posts/4795680942

https://docs.google.com/presentation/d/e/2PACX-1vQylQBOkkMOjbOHPXTXQy3Cxrma-S-BaFpxBqURd0r91S3Fvp4ptMiiklHYzJvhLGf1uzEJLwGfn9UO/pub?start=true&loop=true&delayms=3000

https://docs.google.com/spreadsheets/d/e/2PACX-1vQbuA6iEiH1CzcJp9HIVr6GYQIq15Fb9VM6gHCscGesld-CjTWMvw19yxCOS0jubTnHwSAAnYkJZ-Sv/pubhtml

https://docs.google.com/drawings/d/e/2PACX-1vQ3uOIBHKYX4dyIHr68c9Q8VM_HwUPBI8pASmWh7TAF5MvPEFw2q0CpicCf2vCJpX1e0iI8mubf1dDQ/pub?w=960&h=720

https://docs.google.com/drawings/d/e/2PACX-1vR7ivrf4a1zYR3m5UZMU1Cf4g_Ee6mQCcjbwePo-WZihYOYvq8JwtKCUhcfkT1a7ZF8up4GBi6-jN4c/pub?w=960&h=720

https://docs.google.com/drawings/d/e/2PACX-1vTI31dZS0ZiAqy-OkBq6Jy87SC35NevFEa4L4rkwORvjXVOhmvL-TiuDBG9vpZaIw_1hA3duTkUF6SV/pub?w=960&h=720

https://www.google.com/maps/d/edit?mid=1qO_t_wr7Iu2LzHVkmAak6oka9MevYgA&usp=sharing

https://sites.google.com/view/betop24/%ED%99%88

https://sites.google.com/view/betop24online/%ED%99%88

https://forms.gle/KZ6riHkPr4o4CtE56

https://linktr.ee/betop24

https://taplink.cc/betop24

https://sleek.bio/betop24

https://betop24.carrd.co/

https://solo.to/betop24

https://biolinky.co/betop24

https://paste.myst.rs/ygke48wm

https://pasteio.com/xVgdrVZYdk0p

https://apaste.info/nYTW

https://apaste.info/x5f0

https://pasteio.com/xsgR7oZ7rU9Q

http://bit.ly/3mSEOju

https://cutt.ly/E4furTX

https://paste.myst.rs/e92azm2g

https://controlc.com/858d2580

https://www.google.co.il/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html/

https://www.google.rs/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://maps.google.com.ni/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://ref.gamer.com.tw/redir.php?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.lt/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.ae/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.si/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.com.co/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.google.fi/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://cse.google.fi/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.google.com.sg/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.hr/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://images.google.co.nz/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://qatar.vcu.edu/?URL=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.com.pe/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.ee/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.lv/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.com.pk/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://maps.google.com.np/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://maps.google.co.ve/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.lk/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.com.bd/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.com.ec/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.by/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://maps.google.cz/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.com.ng/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.lu/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.com.uy/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.co.cr/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.tn/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.london.umb.edu/?URL=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.com.do/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.com.pr/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://ceskapozice.lidovky.cz/redir.aspx?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.ba/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.mu/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.co.ke/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.is/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.com.lb/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.com.gt/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://maps.google.com.py/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://maps.google.dz/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.cat/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.hn/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.com.bo/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.com.mt/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.kz/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.com.kh/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.cm/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.com.sv/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://maps.google.ci/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.jo/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://maps.google.com.bh/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.com.pa/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.co.bw/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.am/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.az/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://maps.google.ge/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.com.cu/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.com.kw/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.co.ma/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.com.gh/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.mk/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.co.ug/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://maps.google.as/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.ad/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.astro.wisc.edu/?URL=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.astro.wisc.edu/?URL=/https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://maps.google.cd/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.com.cy/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.bs/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.google.com.mx/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://images.google.hu/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.li/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.com.bz/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.com.af/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.com.ag/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.bi/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.mn/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://maps.google.tt/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.com.na/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.com.qa/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.sn/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.al/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.fm/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.iq/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.com.gi/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.je/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.mg/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.com.om/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.dj/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.com.ly/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.com.jm/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.com.et/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.md/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.sh/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.co.tz/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.me/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.kg/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.google.mw/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.mw/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.ht/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.rw/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.ms/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.ps/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.com.bn/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://cse.google.pt/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://images.google.pt/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.google.co.id/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.co.ls/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.bf/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.la/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://maps.google.com.fj/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.mv/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.gg/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.triathlon.org/?URL=/https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.google.com.ar/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.co.mz/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.google.co.th/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.gm/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.google.no/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.gl/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://maps.google.co.za/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://images.google.ro/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://cse.google.com.vn/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://cse.google.com.ph/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://wikimapia.org/external_link?url=http://https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://images.google.com.pk/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://maps.google.gr/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.gp/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.google.ie/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.bg/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.com/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.cssdrive.com/?URL=/https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.google.sk/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.google.co.il/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://cse.google.rs/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.earth-policy.org/?URL=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://maps.google.lt/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://maps.google.ae/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.google.com.co/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://maps.google.hr/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://community.cypress.com/external-link.jspa?url=http://https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://community.rsa.com/external-link.jspa?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.pasco.k12.fl.us/?URL=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://cse.google.com/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://maps.google.ee/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://maps.google.lv/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.google.com.np/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.bookmerken.de/?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://maps.google.co.ve/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://maps.google.com.ec/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://cse.google.com.bd/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://maps.google.by/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://maps.google.lu/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://images.google.com.uy/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.google.co.cr/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://cse.google.tn/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.google.mu/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.fuzokubk.com/cgi-bin/LinkO.cgi?u=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://images.google.com.pr/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://legacy.aom.org/verifymember.asp?nextpage=http://https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.novalogic.com/remote.asp?NLink=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.orthodoxytoday.org/?URL=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://bukkit.org/proxy.php?link=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.searchdaimon.com/?URL=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://icecap.us/?URL=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.adminer.org/redirect/?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.arakhne.org/redirect.php?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.raincoast.com/?URL=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://4vn.eu/forum/vcheckvirus.php?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://holidaykitchens.com/?URL=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.adhub.com/cgi-bin/webdata_pro.pl?cgifunction=clickthru&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://client.paltalk.com/client/webapp/client/External.wmt?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.virtual-egypt.com/framed/framed.cgi?url==https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.webclap.com/php/jump.php?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://urlxray.com/display.php?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://daidai.gamedb.info/wiki/?cmd=jumpto&r=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.hobowars.com/game/linker.php?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.clevelandbay.com/?URL=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.wheretoskiandsnowboard.com/?URL=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://archive.paulrucker.com/?URL=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://openroadbicycles.com/?URL=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.onesky.ca/?URL=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.sjpcommunications.org/?URL=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.stmarysbournest.com/?URL=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://jc-log.jmirus.de/?URL=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.shamelesstraveler.com/?URL=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://ilns.ranepa.ru/bitrix/rk.php?goto=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://inva.gov.kz/ru/redirect?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://m.fishki.net/go/?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.rospotrebnadzor.ru/bitrix/redirect.php?event1=file&event2=download&event3=prilozheniya-k-prikazu-1018.doc&goto=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://76-rus.ru/bitrix/redirect.php?event1=catalog_out&event2=http2FEEECEBEEE3%EEEE-E5F1FBEDF0&goto=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://cenproxy.mnpals.net/login?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://oca.ucsc.edu/login?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.hyiphistory.com/visit.php?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.liveinternet.ru/journal_proc.php?action=redirect&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://old.fishki.net/go/?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.banki.ru/away/?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.institutoquinquelamartin.edu.ar/Administracion/top-10-cuadros-mas-famosos6-1/?unapproved=10807https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://mcpedl.com/leaving/?url=https%3A%2F%2Fwww.statusvideosongs.in%2F&cookie_check=1https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://gelendzhik.org/bitrix/redirect.php?event1=&event2=&event3=&goto=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://sasisa.ru/forum/out.php?link=%3F&yes=1https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://usolie.info/bitrix/redirect.php?event1=&event2=&event3=&goto=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://vologda-portal.ru/bitrix/redirect.php?event1=news_out&event2=farsicontent.blogspot.com&event3=C1CEAB8CEBE5F1AAFFF2EAA0F8E0C2A5F120EAAEFBEAF1B1E2F0E8A4FF29&goto=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://vstu.ru/bitrix/rk.php?goto=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.bsaa.edu.ru/bitrix/rk.php?goto=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.geogr.msu.ru/bitrix/rk.php?goto=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://academy.1c-bitrix.ru/bitrix/redirect.php?event1=acsdemy&event2=usable&event3=&goto=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://adamb-bartos.blog.idnes.cz/redir.aspx?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://adamburda.blog.idnes.cz/redir.aspx?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://adammikulasek.blog.idnes.cz/redir.aspx?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://adamvanek.blog.idnes.cz/redir.aspx?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://adamvasina.blog.idnes.cz/redir.aspx?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://agalarov.blog.idnes.cz/redir.aspx?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://alenapekarova.blog.idnes.cz/redir.aspx?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://alenapitrova.blog.idnes.cz/redir.aspx?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://alesbeseda.blog.idnes.cz/redir.aspx?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://alesmerta.blog.idnes.cz/redir.aspx?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://alexova.blog.idnes.cz/redir.aspx?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://andreanovotna1.blog.idnes.cz/redir.aspx?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://maps.google.com/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.google.com/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.co.uk/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.fr/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://maps.google.es/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://maps.google.ca/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.nl/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.marcellusmatters.psu.edu/?URL=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.com.au/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://v1.addthis.com/live/redirect/?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://images.google.de/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://maps.google.be/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://maps.google.ru/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.google.se/url?sa=t&source=web&cd=1&ved=0CBcQFjAA&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.se/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://maps.google.com.tr/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.dk/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.com.hk/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.com.mx/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.hu/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.com.au/url?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://maps.google.pt/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.co.nz/url?sr=1&ct2=jp/0_0_s_0_1_a&sa=t&usg=AFQjCNHJ_EDQ-P32EiJs6GJXly0yVYLfVg&cid=52779144202766&url=http://https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.com.ar/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.co.th/url?sa=i&rct=j&q=&esrc=s&source=images&cd=&cad=rja&uact=8&ved=0ahUKEwjB4_-A3tnWAhWHOY8KHTcgDxMQjRwIBw&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.co.th/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.com.ua/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.no/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.co.za/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.ro/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.com.vn/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://guru.sanook.com/?URL=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.com.ph/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://wikimapia.org/external_link?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://maps.google.cl/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.ie/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://fjb.kaskus.co.id/redirect?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://maps.google.com.my/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://www.google.sk/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://images.google.com/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.google.com.tw/url?sa=t&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.morrowind.ru/redirect/grillages-wunschel.fr/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.htmlfeft/ref/xiswi/

https://smmry.com/xn-herzrhythmusstrungen-hbc.biz/goto.php?site=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.ut2.ru/redirect/slrc.org/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://jump.5ch.net/?blingguard.com/?URL=betop24.com/hera-casino

https://jump.5ch.net/?ponsonbyacupunctureclinic.co.nz/?URL=betop24.com/hera-casino

http://bios.edu/?URL=puttyandpaint.com/?URL=betop24.com/hera-casino

https://cwcab.com/?URL=eaglesgymnastics.com/?URL=betop24.com/hera-casino

http://www.ut2.ru/redirect/weburg.net/redirect?url=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://2ch.io/assertivenorthwest.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.morrowind.ru/redirect/slighdesign.com/?URL=betop24.com/hera-casino

http://ime.nu/gumexslovakia.sk/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.morrowind.ru/redirect/roserealty.com.au/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.allods.net/redirect/magenta-mm.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://bios.edu/?URL=shavermfg.com/?URL=betop24.com/hera-casino

http://www.allods.net/redirect/healthyeatingatschool.ca/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.htmlfeft/ref/xiswi/

http://www.gta.ru/redirect/dcfossils.org/?URL=betop24.com/hera-casino

https://jump.5ch.net/?pro-net.se/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://bios.edu/?URL=civicvoice.org.uk/?URL=betop24.com/hera-casino

https://jump.5ch.net/?arbor-tech.be/?URL=betop24.com/hera-casino

http://www.allods.net/redirect/theaustonian.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://ime.nu/basebusiness.com.au/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://cwcab.com/?URL=hfw1970.de/redirect.php?url=betop24.com/hera-casino

http://www.ut2.ru/redirect/firma.hr/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.nwnights.ru/redirect/giruna.hu/redirect.php?url=betop24.com/hera-casino

http://bios.edu/?URL=weburg.net/redirect?url=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.gta.ru/redirect/emotional.ro/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.gta.ru/redirect/couchsrvnation.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.htmlfeft/ref/xiswi/

http://www.allods.net/redirect/turbo-x.hr/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.gta.ru/redirect/albins.com.au/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.ut2.ru/redirect/emophilips.com/?URL=betop24.com/hera-casino

http://bios.edu/?URL=pcrnv.com.au/?URL=betop24.com/hera-casino

http://2ch.io/md-technical.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.htmlfeft/ref/xiswi/

http://www.ut2.ru/redirect/stcroixblades.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://jump.5ch.net/?sassyj.net/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.nwnights.ru/redirect/applicationadvantage.com/?URL=betop24.com/hera-casino

http://www.ut2.ru/redirect/hotyoga.co.nz/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://bios.edu/?URL=boc-ks.com/speedbump.asp?link=betop24.com/hera-casino

http://www.morrowind.ru/redirect/accord.ie/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://ime.nu/s79457.gridserver.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://2ch.io/morrowind.ru/redirect/3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.htmlfeft/ref/xiswi/

https://smmry.com/centre.org.au/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://ime.nu/pulaskiticketsandtours.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://smmry.com/promoincendie.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.htmlfeft/ref/xiswi/

http://www.nwnights.ru/redirect/hs-events.nl/?URL=betop24.com/hera-casino

http://www.ut2.ru/redirect/chivemediagroup.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.htmlfeft/ref/xiswi/

http://www.nwnights.ru/redirect/horizon-environ.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.morrowind.ru/redirect/yesfest.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://bios.edu/?URL=cssanz.org/?URL=betop24.com/hera-casino

http://bios.edu/?URL=roserealty.com.au/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.morrowind.ru/redirect/t.me/iv?url=betop24.com/hera-casino

http://www.allods.net/redirect/boosterblog.com/vote-815901-624021.html?adresse=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.ut2.ru/redirect/client.paltalk.com/client/webapp/client/External.wmt?url=betop24.com/hera-casino

http://www.morrowind.ru/redirect/minecraft-galaxy.ru/redirect/?url=betop24.com/hera-casino

http://www.nwnights.ru/redirect/rescuetheanimals.org/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://ime.nu/foosball.com/?URL=betop24.com/hera-casino

http://www.ut2.ru/redirect/supertramp.com/?URL=betop24.com/hera-casino

http://www.allods.net/redirect/gmmdl.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.htmlfeft/ref/xiswi/

http://2ch.io/icecap.us/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.htmlfeft/ref/xiswi/

http://www.nwnights.ru/redirect/labassets.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://cwcab.com/?URL=acceleweb.com/register?aw_site_id=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.allods.net/redirect/cim.bg/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://ime.nu/rawseafoods.com/?URL=betop24.com/hera-casino

https://cwcab.com/?URL=judiisrael.com/?URL=betop24.com/hera-casino

http://bios.edu/?URL=roserealty.com.au/?URL=betop24.com/hera-casino

http://www.morrowind.ru/redirect/wdvstudios.be/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.htmlfeft/ref/xiswi/

https://jump.5ch.net/?frienddo.com/out.php?url=betop24.com/hera-casino

https://jump.5ch.net/?ctlimo.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.htmlfeft/ref/xiswi/

http://www.ut2.ru/redirect/bvilpcc.com/?URL=betop24.com/hera-casino

https://cwcab.com/?URL=reedring.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.ut2.ru/redirect/lbaproperties.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.htmlfeft/ref/xiswi/

http://ime.nu/kingswelliesnursery.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://smmry.com/miloc.hr/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://smmry.com/nslgames.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://bios.edu/?URL=thebigmo.nl/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.nwnights.ru/redirect/steamcommunity.com/linkfilter/?url=betop24.com/hera-casino

http://2ch.io/barrypopik.com/index.php?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://cwcab.com/?URL=batterybusiness.com.au/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://smmry.com/blingguard.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.htmlfeft/ref/xiswi/

https://cwcab.com/?URL=professor-murmann.info/?URL=betop24.com/hera-casino

http://www.allods.net/redirect/burkecounty-ga.gov/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://2ch.io/2ch.io/betop24.com/hera-casino

http://www.nwnights.ru/redirect/mikropul.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://cwcab.com/?URL=bytecheck.com/results?resource=betop24.com/hera-casino

http://www.nwnights.ru/redirect/youtube.com/redirect?q=betop24.com/hera-casino

http://www.nwnights.ru/redirect/salonfranchise.com.au/?URL=betop24.com/hera-casino

https://cwcab.com/?URL=couchsrvnation.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://ime.nu/usich.gov/?URL=betop24.com/hera-casino

http://www.nwnights.ru/redirect/sostrategic.com.au/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.allods.net/redirect/boosterblog.net/vote-146-144.html?adresse=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.allods.net/redirect/wilsonlearning.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://ime.nu/nerida-oasis.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.htmlfeft/ref/xiswi/

http://2ch.io/aldonauto.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.allods.net/redirect/spot-car.com/?URL=betop24.com/hera-casino

http://ime.nu/hornbeckoffshore.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://bios.edu/?URL=anzela.edu.au/?URL=betop24.com/hera-casino

http://bios.edu/?URL=lbast.ru/zhg_img.php?url=betop24.com/hera-casino

https://cwcab.com/?URL=dentalcommunity.com.au/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.morrowind.ru/redirect/peter.murmann.name/?URL=betop24.com/hera-casino

http://www.morrowind.ru/redirect/firma.hr/?URL=betop24.com/hera-casino

https://jump.5ch.net/?labassets.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.htmlfeft/ref/xiswi/

http://ime.nu/progressprinciple.com/?URL=betop24.com/hera-casino

http://www.nwnights.ru/redirect/mbcarolinas.org/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://jump.5ch.net/?fotka.com/link.php?u=betop24.com/hera-casino

http://bios.edu/?URL=restaurant-zahnacker.fr/?URL=betop24.com/hera-casino

https://cwcab.com/?URL=accord.ie/?URL=betop24.com/hera-casino

http://www.nwnights.ru/redirect/morrisparks.net/?URL=betop24.com/hera-casino

https://cwcab.com/?URL=fishidy.com/go?url=betop24.com/hera-casino

http://www.nwnights.ru/redirect/blingguard.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.htmlfeft/ref/xiswi/

http://www.ut2.ru/redirect/ria-mar.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://jump.5ch.net/?batterybusiness.com.au/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://bios.edu/?URL=ocmdhotels.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.gta.ru/redirect/healthyeatingatschool.ca/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.htmlfeft/ref/xiswi/

https://cwcab.com/?URL=ntltyres.com.au/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://jump.5ch.net/?romanodonatosrl.com/?URL=betop24.com/hera-casino

http://www.morrowind.ru/redirect/pcrnv.com.au/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.htmlfeft/ref/xiswi/

http://bios.edu/?URL=wup.pl/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://jump.5ch.net/?bluewatergrillri.com/?URL=betop24.com/hera-casino

http://2ch.io/washburnvalley.org/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://smmry.com/crspublicity.com.au/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.allods.net/redirect/vectechnologies.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://smmry.com/troxellwebdesign.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://jump.5ch.net/?jacobberger.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.htmlfeft/ref/xiswi/

http://www.ut2.ru/redirect/oncreativity.tv/?URL=betop24.com/hera-casino

http://www.allods.net/redirect/ww2.torahlab.org/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://2ch.io/essencemusicagency.com/?URL=betop24.com/hera-casino

http://www.ut2.ru/redirect/livingtrustplus.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://cwcab.com/?URL=giruna.hu/redirect.php?url=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.nwnights.ru/redirect/cssdrive.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.htmlfeft/ref/xiswi/

http://bios.edu/?URL=basebusiness.com.au/?URL=betop24.com/hera-casino

http://www.allods.net/redirect/2ch.io/3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html http://2ch.io/slrc.org/?URL=betop24.com/hera-casino

http://www.nwnights.ru/redirect/life-church.com.au/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://bios.edu/?URL=precisioncomponents.com.au/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.nwnights.ru/redirect/okellymoylan.ie/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://ime.nu/sc.hkexnews.hk/TuniS/3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://www.allods.net/redirect/davidcouperconsulting.com/?URL=betop24.com/hera-casino

https://jump.5ch.net/?morrowind.ru/redirect/betop24.com/hera-casino

http://www.morrowind.ru/redirect/ucrca.org/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://jump.5ch.net/?wagyu.org/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://jump.5ch.net/?unbridledbooks.com/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.htmlfeft/ref/xiswi/

http://www.allods.net/redirect/jongeriuslab.com/?URL=betop24.com/hera-casino

https://smmry.com/woodforestcharitablefoundation.org/?URL=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

www.waters.com/waters/downloadFile.htm?lid=134799103&id=134799102&fileName=Download&fileUrl=http%3A%2F%2Fbetop24.com/hera-casino

www.bari91.com/tz.php?zone=Pacific/Niue&r=http%3A%2F%2Fbetop24.com/hera-casino

www.xfdq123.com/url.aspx?url=https://betop24.com/hera-casino

www.ignicaodigital.com.br/affiliate/?idev_id=270&u=https://betop24.com/hera-casino

www.mirogled.com/banner-clicks/10?url=https://betop24.com/hera-casino

www.haveanice.com/refer/D3dKFDIUbYk66eqlL1163PlAW3BXqx/jpg?hvAn_url=https://betop24.com/hera-casino

www.avilas-style.com/shop/affiche.php?ad_id=132&from=&uri=betop24.com/hera-casino

www.hentaicrack.com/cgi-bin/atx/out.cgi?s=95&u=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

www.voxlocalis.net/enlazar/?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://christchurchcitylibraries.com/Databases/GVRL/jumpto.asp?url=http%3A%2F%2Fbetop24.com/hera-casino

www.ferrosystems.com/setLocale.jsp?language=en&url=https://betop24.com/hera-casino

test.healinghealth.com/?wptouch_switch=desktop&redirect=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

www.lastdates.com/l/?betop24.com/hera-casino

kaimono-navi.jp/rd?u=http%3A%2F%2Fbetop24.com/hera-casino

www.shop-bell.com/out.php?id=kibocase&category=ladies&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://richmonkey.biz/go/?https://betop24.com/hera-casino

https://online-knigi.com/site/getlitresurl?url=http%3A%2F%2Fbetop24.com/hera-casino

akvaforum.no/go.cfml?id=1040&uri=https://betop24.com/hera-casino

www.kamphuisgroep.nl/r.php?cid=2314&site=https://betop24.com/hera-casino

sns.51.ca/link.php?url=https://betop24.com/hera-casino

http://newsrankey.com/view.html?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

www.minibuggy.net/forum/redirect-to/?redirect=https://betop24.com/hera-casino

www.wagersmart.com/top/out.cgi?id=bet2gold&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

www.global-autonews.com/shop/bannerhit.php?bn_id=307&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

pnevmopodveska-club.ru/index.php?app=core&module=system&controller=redirect&do=redirect&url=https://betop24.com/hera-casino

www.darussalamciamis.or.id/redirect/?alamat=http%3A%2F%2Fbetop24.com/hera-casino

agama.su/go.php?url=https://betop24.com/hera-casino

bas-ip.ru/bitrix/rk.php?goto=https://betop24.com/hera-casino

college.captainu.com/college_teams/1851/campaigns/51473/tracking/click?contact_id=1154110&email_id=1215036&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

www.oldfold.com/g?u=https://betop24.com/hera-casino

www.anibox.org/go?https://betop24.com/hera-casino

https://acejobs.net/jobclick/?RedirectURL=http%3A%2F%2Fbetop24.com/hera-casino&Domain=acejobs.net

www.m.mobilegempak.com/wap_api/get_msisdn.php?URL=https://www.3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

sitesdeapostas.co.mz/track/odd?url-id=11&game-id=1334172&odd-type=draw&redirect=https://betop24.com/hera-casino

www.autaabouracky.cz/plugins/guestbook/go.php?url=https://www.3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

www.escapers-zone.net/ucp.php?mode=logout&redirect=http%3A%2F%2Fbetop24.com/hera-casino

http://canuckstuff.com/store/trigger.php?rlink=https://betop24.com/hera-casino

members.practicegreenhealth.org/eweb/Logout.aspx?RedirectURL=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://fiinpro.com/Home/ChangeLanguage?lang=vi-VN&returnUrl=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://visit-thassos.com/index.php/language/en?redirect=https://betop24.com/hera-casino

adserverv6.oberberg.net/adserver/www/delivery/ck.php?ct=1&oaparams=2bannerid=2zoneid=35cb=88915619faoadest=https://betop24.com/hera-casino

www.homuta.co.jp/link/?link=http%3A%2F%2Fbetop24.com/hera-casino

klvr.link/redirect/venividivici/spotify?linkUrl=http%3A%2F%2Fbetop24.com/hera-casino

www.pcstore.com.tw/adm/act.htm?src=vipad_click&store_type=SUP_TOP&big_exh=STOREAD-%A7%E950&reurl=http%3A%2F%2Fbetop24.com/hera-casino

http://baantawanchandao.com/change_language.asp?language_id=th&MemberSite_session=site_47694_&link=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

grannyfuck.in/cgi-bin/atc/out.cgi?id=139&u=https://betop24.com/hera-casino

www.joserodriguez.info/?wptouch_switch=desktop&redirect=https://betop24.com/hera-casino

https://navigraph.com/redirect.ashx?url=https://betop24.com/hera-casino

edu54.ru/bitrix/redirect.php?goto=https://betop24.com/hera-casino

https://honolulufestival.com/ja/?wptouch_switch=desktop&redirect=http%3A%2F%2Fbetop24.com/hera-casino

www.perinosboilingpot.com/site.php?pageID=1&bannerID=19&vmoment=1430132758&url=http%3A%2F%2Fbetop24.com/hera-casino

www.hardcoreoffice.com/tp/out.php?link=txt&url=https://www.3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

best.amateursecrets.net/cgi-bin/out.cgi?ses=onmfsqgs6c&id=318&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

elitesm.ru/bitrix/rk.php?id=102&site_id=ru&event1=banner&event2=click&event3=1+%2F+%5B102%5D+%5Bright_group_bot%5D+%DD%CA%CE+3%C4&goto=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

www.iasb.com/sso/login/?userToken=Token&returnURL=https://betop24.com/hera-casino

prominentjobs.co.uk/jobclick/?RedirectURL=http%3A%2F%2Fbetop24.com/hera-casino

http://workshopweekend.net/er?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

go.pnuna.com/go.php?url=https://betop24.com/hera-casino

https://przyjazniseniorom.com/language/en/?returnUrl=http%3A%2F%2Fbetop24.com/hera-casino

motorrad-stecki.de/trigger.php?r_link=http%3A%2F%2Fbetop24.com/hera-casino

news.animravel.fr/retrolien.aspx?id_dest=1035193&id_envoi=463&url=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://aldenfamilyonline.com/KathySite/MomsSite/MOM_SHARE_MEMORIES/msg_system/go.php?url=https://betop24.com/hera-casino

www.sports-central.org/cgi-bin/axs/ax.pl?https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

shop.mediaport.cz/redirect.php?action=url&goto=betop24.com/hera-casino

adlogic.ru/?goto=jump&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

www.medicumlaude.de/index.php/links/index.php?url=https://betop24.com/hera-casino

www.figurama.eu/cz/redirect.php?path=https://betop24.com/hera-casino

nagranitse.ru/url.php?q=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

www.wien-girls.at/out-link?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

www.blackpictures.net/jcet/tiov.cgi?cvns=1&s=65&u=https://betop24.com/hera-casino

https://athleticforum.biz/redirect/?to=http%3A%2F%2Fbetop24.com/hera-casino

www.telehaber.com/redir.asp?url=https://betop24.com/hera-casino

www.elmore.ru/go.php?to=https://betop24.com/hera-casino

www.tido.al/vazhdo.php?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

os-company.ru/bitrix/redirect.php?goto=https://betop24.com/hera-casino

duma-slog.ru/bitrix/redirect.php?event1=file&event2=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html&event3=29.01.2015_312_rd.doc&goto=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

www.interempresas.net/estadisticas/r.asp?idsector=129&e=221083&c=195&d=https://betop24.com/hera-casino

pravoslavieru.trckmg.com/app/click/30289/561552041/?goto_url=betop24.com/hera-casino

jump.fan-site.biz/rank.cgi?mode=link&id=342&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

http://anti-kapitalismus.org/sites/all/modules/pubdlcnt/pubdlcnt.php?file=https://betop24.com/hera-casino&nid=435

rubyconnection.com.au/umbraco/newsletterstudio/tracking/trackclick.aspx?nid=207065033113056034011005043041220243180024215107&e=011204127253056232044128247253046214192002250116195220062107112232157159227010159247231011081075001197133136091194134170178051032155159001112047&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

video.childsheroes.com/Videos/SetCulture?culture=en-US&returnURL=http%3A%2F%2Fbetop24.com/hera-casino

buecher-teneues.de/mlm/lm/lm.php?tk=CQkJRkRhdW1AdGVuZXVlcy5jb20JU3BlY2lhbCBPZmZlcnMgYmVpIHRlTmV1ZXMgCTM3CQkzNzQ1CWNsaWNrCXllcwlubw==&url=https://betop24.com/hera-casino

karir.imslogistics.com/language/en?return=https://www.3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

yun.smartlib.cn/widgets/fulltext/?url=https://betop24.com/hera-casino

www.okhba.org/clicks.php?bannerid=51&url=http%3A%2F%2Fbetop24.com/hera-casino

www.all1.co.il/goto.php?url=https://www.3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

https://jipijapa.net/jobclick/?RedirectURL=http%3A%2F%2Fbetop24.com/hera-casino&Domain=jipijapa.net&rgp_m=co3&et=4495

chaku.tv/i/rank/out.cgi?url=https://betop24.com/hera-casino

www.mendocino.com/?id=4884&url=betop24.com/hera-casino

doc.enervent.com/op/op.SetLanguage.php?lang=de_DE&referer=http%3A%2F%2Fbetop24.com/hera-casino

www.feg-jena.de/link/?link=https://betop24.com/hera-casino

b2b.psmlighting.be/en-GB/Base/ChangeCulture?currentculture=de-DE¤turl=http%3A%2F%2Fbetop24.com/hera-casino¤turl=http%3A%2F%2Fbatmanapollo.ru

http://dstats.net/redir.php?url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

crescent.netcetra.com/inventory/military/dfars/?saveme=MS51957-42*&redirect=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

r5.dir.bg/rem.php?word_id=0&place_id=9&ctype=mp&fromemail=&iid=3770&aid=4&cid=0&url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

www.store-datacomp.eu/Home/ChangeLanguage?lang=en&returnUrl=http%3A%2F%2Fbetop24.com/hera-casino

http://hotgrannyworld.com/cgi-bin/crtr/out.cgi?id=41&l=toplist&u=https://betop24.com/hera-casino

t.wxb.com/order/sourceUrl/1894895?url=3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

shop.merchtable.com/users/authorize?return_url=https://3cave0.blogspot.com/2023/02/why-are-there-no-genuine-land-based.html

zharpizza.ru/bitrix/rk.php?goto=https://betop24.com/hera-casino

elinks.qp.land.to/link.php?url=https://betop24.com/hera-casino