Over the last 3 months we have been working hard on offering you full frame laser coping. We can not thank UTA Formula Racing Team enough for all the support and help they have given to us throughout this process.

WHAT IS LASER CUTTING?

Laser cutting is a technology that has been in use since the 1960s. Basically, it involves using a laser to cut material. It is an automated computerized process that points a high-power laser at material which causes it to melt, burn or vaporize away. It leaves a high-quality surface finish that is free of burrs. Lasers can be used to cut all types of materials including wood, plastics and metals. They can cut flat materials as well as tubular shaped. Lasers can provide endless intricate shapes and designs that cannot be achieved with other cutting methods.

ADVANTAGES OF LASER TECHNOLOGY

Laser technology is a quality enhancing manufacturing process that offers more possibilities than virtually any other traditional machining process. It can eliminate the need for machining on many jobs enabling customers to reduce their manufacturing costs. Advantages include:

- Enhanced precision

- Better edge quality

- Ability to cut complex shapes without the need for tooling

- Faster speed

- Reduced chance of material warping

- Ability to cut materials that are impossible to cut with more traditional methods

The Laser Coping Process: The latest Adige LT fibers is one of the fastest laser tube cutting machines on the market today. This allows us to cut very complex products such as chassis tubes for the racing industry in a matter of seconds. Our laser machines often provide the most effective process for cutting plate, sheet, or tubing metal for metal fabrication, including carbon steel, stainless steel, aluminum, and many other alloys.

Cost Efficient and Ultimate Flexibility: Our laser cutting equipment includes long bed, 4-axis lasers with power ranging from 2000 to 3200 watts to deliver cost efficient flexibility. Each machine is able to chuck up to 6“ diameter. The 2000 watt fiber machines cut thin wall tubing up to 1/4“ with better accuracy, no burrs and a smooth finish while maintaining a competitive cost in comparison to other mechanical processes. The 3000 and 3200 watt CO2 lasers allow us to cut material up to 24” in diameter and 5/8” thick.

Cutting Large Volumes of Tubular Products: Our vendor has automatic production tube cutting cells with 3200 watts of cutting power. Each machine is equipped with fully automatic tube feeders up to 30 feet, minimizing the challenges and cost of producing large volumes of tubular products. These machines offer the ultimate in power, accuracy and cost reductions as well as tolerances of +/- 0.005“ in profiling or cut-to-length.

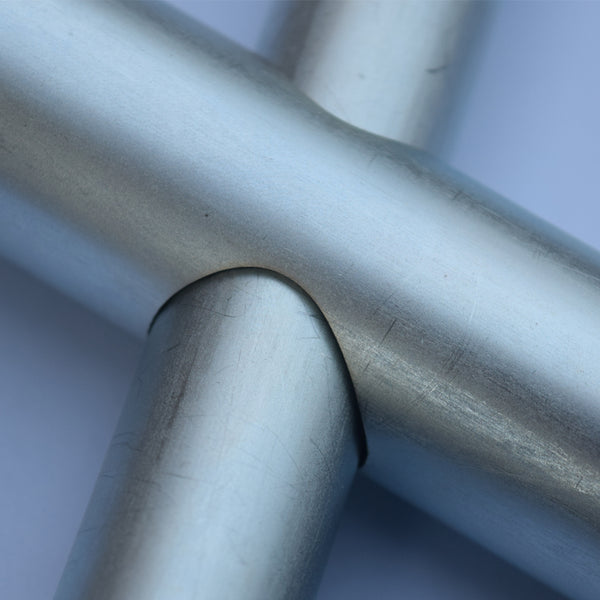

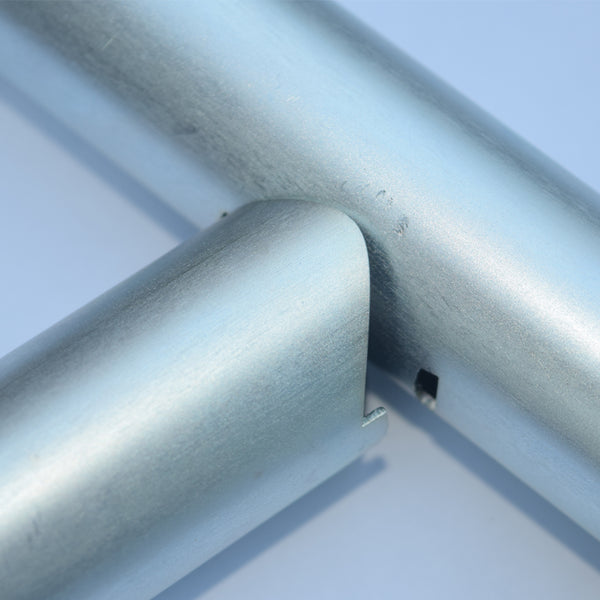

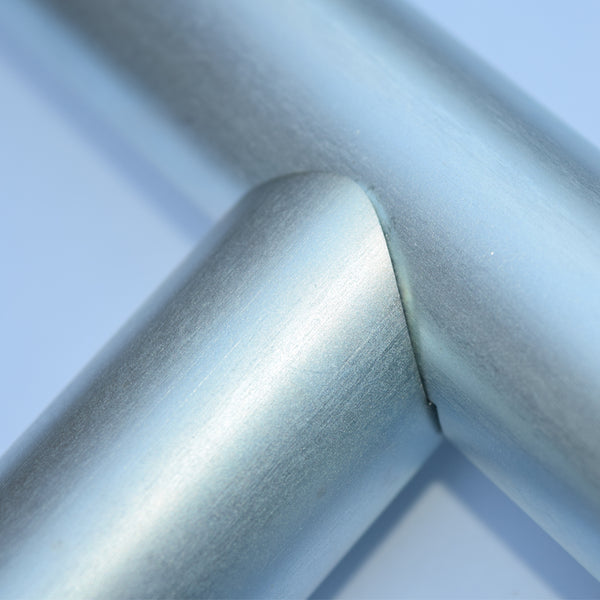

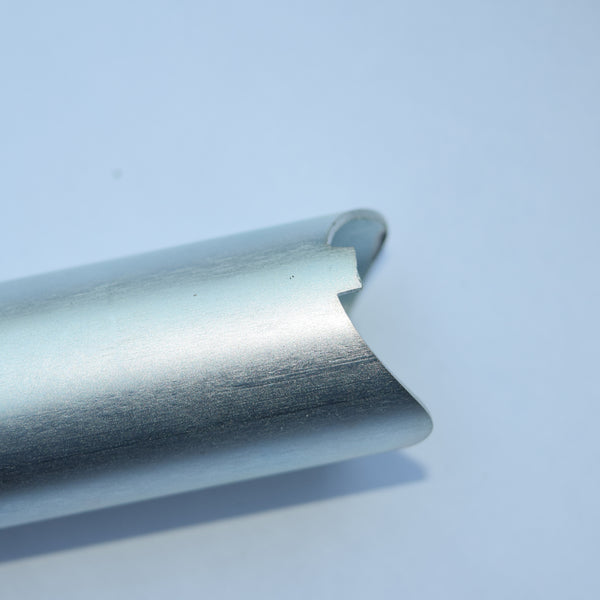

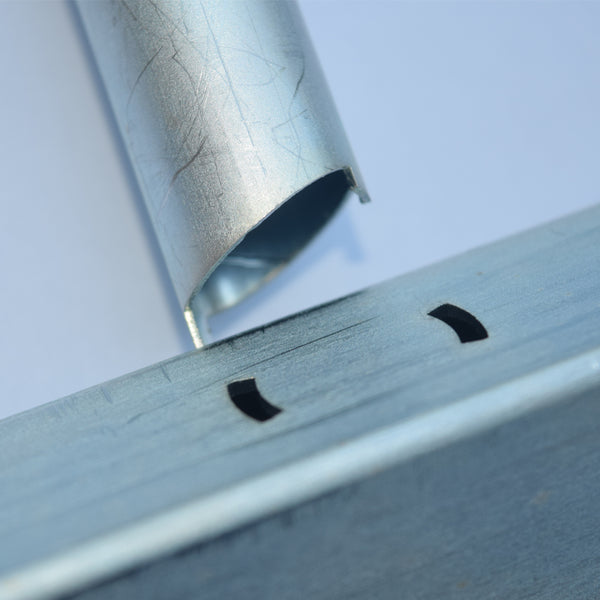

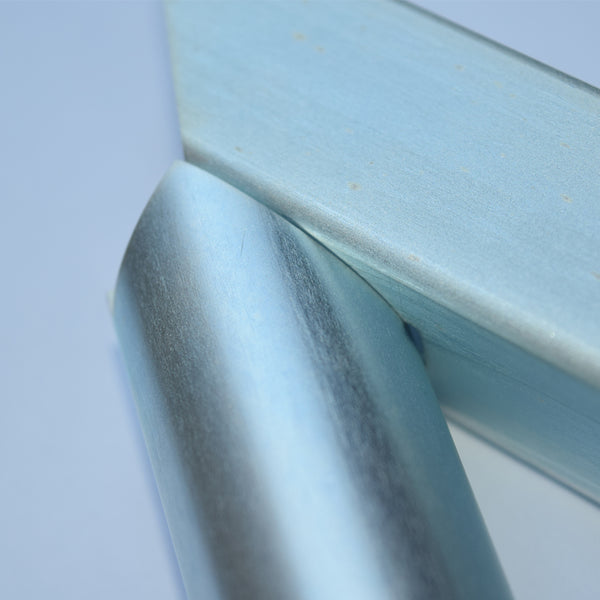

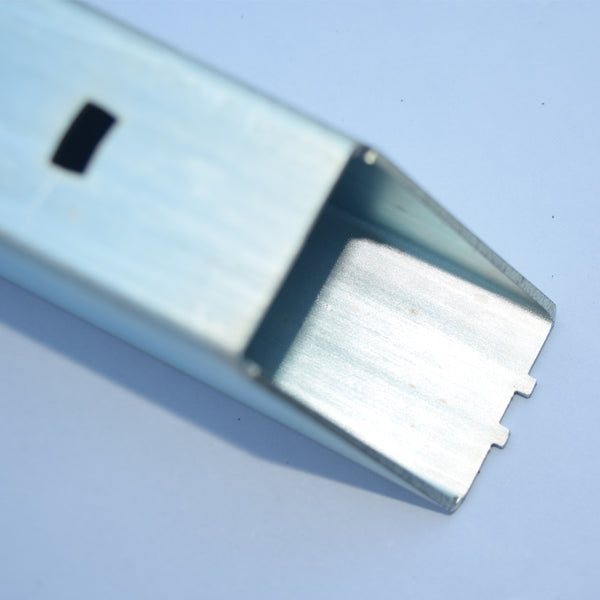

Check out some of the example cuts bellow! The tubes in the pictures below are 4130 Chrome Molly tubing that has been Zinc plated for demo purposes only. The Zinc plating is just to keep it from rusting when we take the sample laser coped tubes to races and tradeshows.

Round Thru Coping:

Round Coping With Alignment Pins:

Round Coping With Alignment Pins:

Round Coping With Alignment Pins:

Round Coping Alignment Pin:

Round To Square Coping With Alignment Pins:

Round To Square Coping With Alignment Pins:

Round To Square Coping With Alignment Pins:

Round To Square Coping With Alignment Pins:

Square Coping Alignment Pins:

Our Goals:

Our goal at FSAEparts is to offer you the best discounts we can. In this case we have set up a partnership for this laser coping process. We have had two sample frames made and a few sample displays to prove out the process. We now have a streamline process which offers great prices and outstanding quality.

Breakdown:

**Prices will vary due to the complexity of the frame and the amount of tubes. This estimated figure is based off what we considered to be a more advanced steel space frame.****

- One frame design sent to us at any given time

- Estimated cost of $2,200 USD (This includes material and all laser coping)

- Ten different frame designs all sent in by a certain date

- Estimated cost of $1,300 USD (This includes material and all laser coping)

The more teams that submit designs the cheaper the cost. The reason for this is that the laser coping machine takes some time to set up and change out heads for different diameters. The laser machine also has automatic feed capabilities. So say you have 10 teams all using some 1"OD x 0.035"wall for several tubes. The machine would cut all those tubes automatically then sort them out to the proper team, thus driving the cost down.

We will be making a poll on what tube sizes your team uses. Please Please Please keep an eye out for the poll and fill it out when you get it. This will allow for use to offer a list of "standard" sizes to design your car space frame with which will make the final cost even cheaper.

Our ultimate goal is to be able to laser cope your frame cheaper than you can purchase the material! So spread the word and leave your thoughts and comments bellow.

Friends and Family: We've signed up to win a $1000 small business grant and need your help!

Please follow the link to our page at ideacafe.com (search for FSAE) and vote for us! If we win, the money would be a huge help to grow and develop our site to help out the FSAE community even more! Please share with anyone and everyone! Thanks!

Unfortunately you will have to create a free account to vote, so we really appreciate you taking the time to help!!

In case you were not aware: the PRI trade show, in all its glory, is coming up pretty soon! This is a great place for teams to go in search of new sponsors and gain some exposure to the professional racing industry.

Performance Racing Industry Trade Show (PRI)

December 11-13, 2014

Indiana Convention Center, USA

If you're considering attending, check out our PRI post in the "Helpful Tips" blog for some advice on how to have a successful show.

We'll be there and hope you will be too!

This isn't formula but we can all respect some seriously awesome driving.

Monster Energy: Ballistic BJ Baldwin Recoil 2

This is what all our baja friends want when they grow up. I can't lie though, I can think of thousands of things I could do with this. It might not look as good as BJ Baldwin, but I sure would give it a try.

We are teaming up with a company to exhibit at the Performance Racing Industry trade show in December. We can not say who the company is at this time, but keep an eye out for an official announcement.

We think it would be a cool idea to have team unveiling/promo videos running on our TVs during the show. It will be a great opportunity for teams to get some exposure at the biggest performance racing show in the world.

Please send us a link to your video either through email, facebook or right here in the comments below. Closer to the date of the show we will make a survey to allow people to vote on which videos they like the most.

You can post as many videos as you would like.

Here is an unveiling video for Jayhawk Motorsports' 2010 car.

This is an old video but it never gets old to watch! Destructive testing at its best!

Ohio State at the Detroit FSAE competition decides they'd like to have some fun in the practice area.

We've recently added two new partners to our site: Texense and Titanium Engineers!

You can see a bunch of awesome electronics and sensors from Texense in our electronics section. Take a look and if interested please contact Texense to make your order, and make sure to ask for the FSAE discount. Please tell them we sent you!

In the near future we will be selling a variety of titanium stock, courtesy of Titanium Engineers so keep an eye out for that.

On this blog, we will post upcoming events, popular stories, tips and tricks to survive formula car, and much more.

Please keep checking up to see what is new and let us know if you want us to talk about anything or answer any questions you may have.