Formula and Baja laser frame coping

Over the last 3 months we have been working hard on offering you full frame laser coping. We can not thank UTA Formula Racing Team enough for all the support and help they have given to us throughout this process.

WHAT IS LASER CUTTING?

Laser cutting is a technology that has been in use since the 1960s. Basically, it involves using a laser to cut material. It is an automated computerized process that points a high-power laser at material which causes it to melt, burn or vaporize away. It leaves a high-quality surface finish that is free of burrs. Lasers can be used to cut all types of materials including wood, plastics and metals. They can cut flat materials as well as tubular shaped. Lasers can provide endless intricate shapes and designs that cannot be achieved with other cutting methods.

ADVANTAGES OF LASER TECHNOLOGY

Laser technology is a quality enhancing manufacturing process that offers more possibilities than virtually any other traditional machining process. It can eliminate the need for machining on many jobs enabling customers to reduce their manufacturing costs. Advantages include:

- Enhanced precision

- Better edge quality

- Ability to cut complex shapes without the need for tooling

- Faster speed

- Reduced chance of material warping

- Ability to cut materials that are impossible to cut with more traditional methods

The Laser Coping Process: The latest Adige LT fibers is one of the fastest laser tube cutting machines on the market today. This allows us to cut very complex products such as chassis tubes for the racing industry in a matter of seconds. Our laser machines often provide the most effective process for cutting plate, sheet, or tubing metal for metal fabrication, including carbon steel, stainless steel, aluminum, and many other alloys.

Cost Efficient and Ultimate Flexibility: Our laser cutting equipment includes long bed, 4-axis lasers with power ranging from 2000 to 3200 watts to deliver cost efficient flexibility. Each machine is able to chuck up to 6“ diameter. The 2000 watt fiber machines cut thin wall tubing up to 1/4“ with better accuracy, no burrs and a smooth finish while maintaining a competitive cost in comparison to other mechanical processes. The 3000 and 3200 watt CO2 lasers allow us to cut material up to 24” in diameter and 5/8” thick.

Cutting Large Volumes of Tubular Products: Our vendor has automatic production tube cutting cells with 3200 watts of cutting power. Each machine is equipped with fully automatic tube feeders up to 30 feet, minimizing the challenges and cost of producing large volumes of tubular products. These machines offer the ultimate in power, accuracy and cost reductions as well as tolerances of +/- 0.005“ in profiling or cut-to-length.

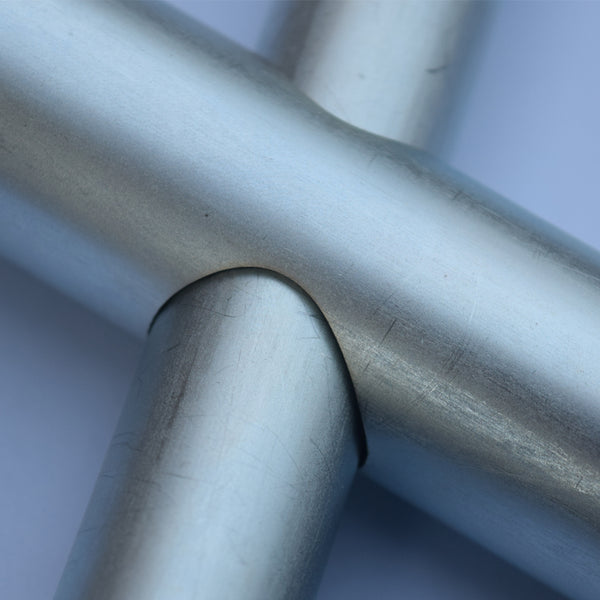

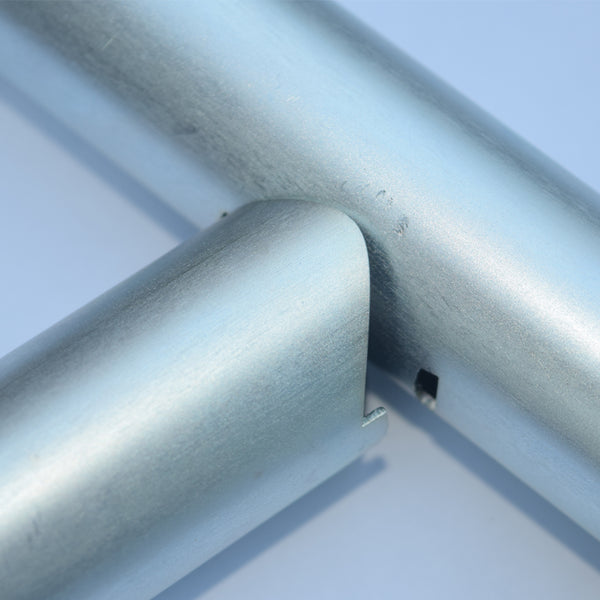

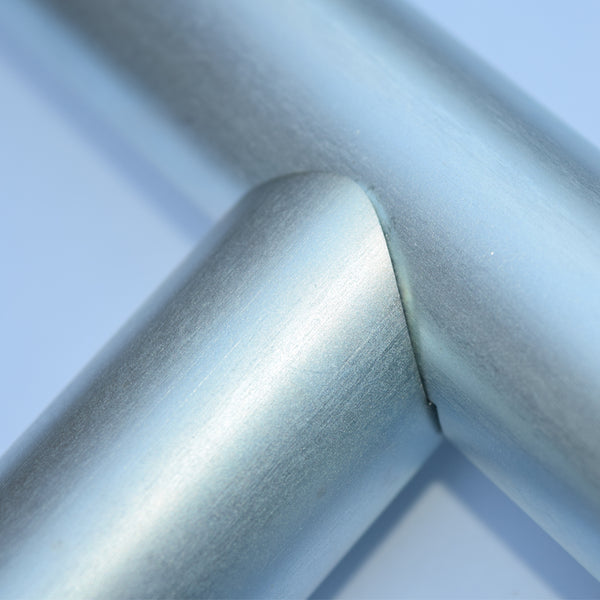

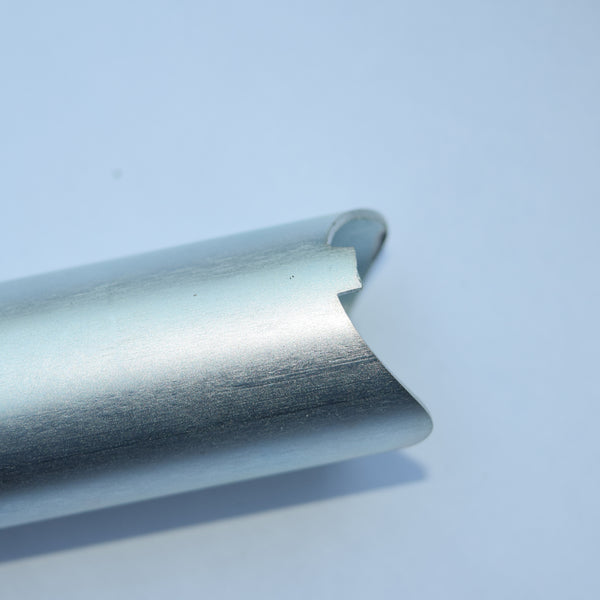

Check out some of the example cuts bellow! The tubes in the pictures below are 4130 Chrome Molly tubing that has been Zinc plated for demo purposes only. The Zinc plating is just to keep it from rusting when we take the sample laser coped tubes to races and tradeshows.

Round Thru Coping:

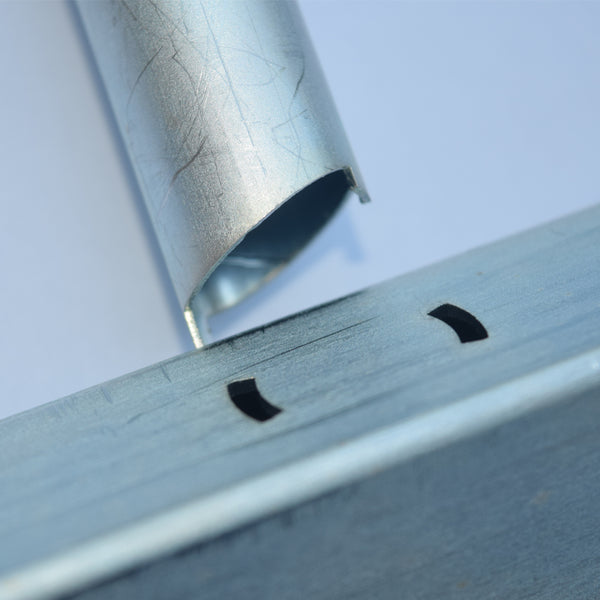

Round Coping With Alignment Pins:

Round Coping With Alignment Pins:

Round Coping With Alignment Pins:

Round Coping Alignment Pin:

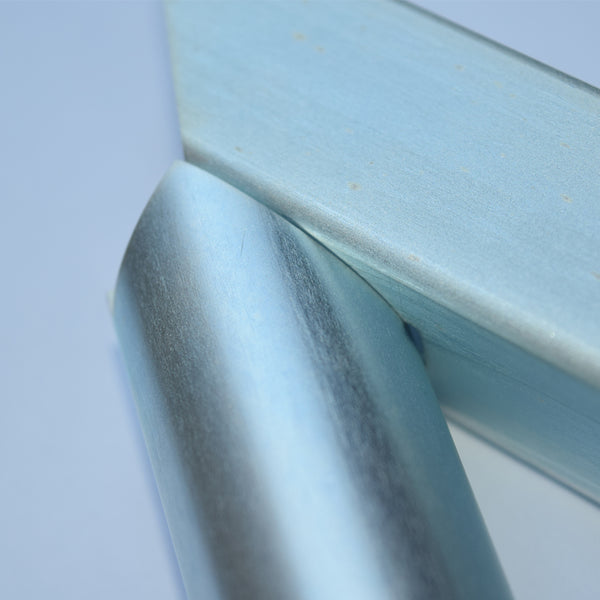

Round To Square Coping With Alignment Pins:

Round To Square Coping With Alignment Pins:

Round To Square Coping With Alignment Pins:

Round To Square Coping With Alignment Pins:

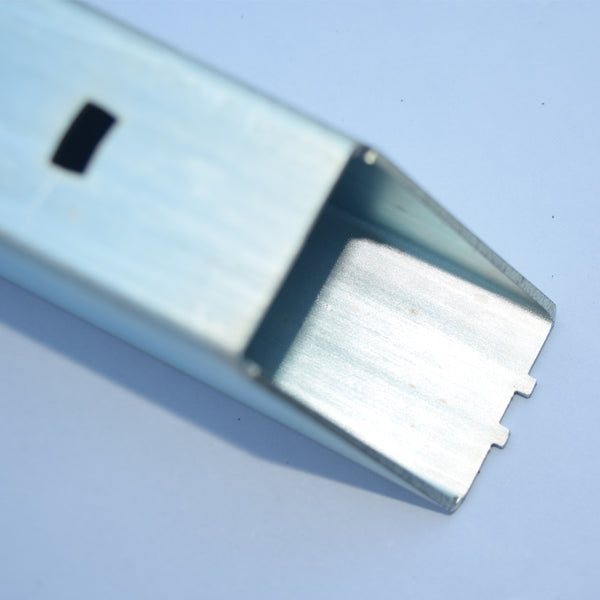

Square Coping Alignment Pins:

Our Goals:

Our goal at FSAEparts is to offer you the best discounts we can. In this case we have set up a partnership for this laser coping process. We have had two sample frames made and a few sample displays to prove out the process. We now have a streamline process which offers great prices and outstanding quality.

Breakdown:

**Prices will vary due to the complexity of the frame and the amount of tubes. This estimated figure is based off what we considered to be a more advanced steel space frame.****

- One frame design sent to us at any given time

- Estimated cost of $2,200 USD (This includes material and all laser coping)

- Ten different frame designs all sent in by a certain date

- Estimated cost of $1,300 USD (This includes material and all laser coping)

The more teams that submit designs the cheaper the cost. The reason for this is that the laser coping machine takes some time to set up and change out heads for different diameters. The laser machine also has automatic feed capabilities. So say you have 10 teams all using some 1"OD x 0.035"wall for several tubes. The machine would cut all those tubes automatically then sort them out to the proper team, thus driving the cost down.

We will be making a poll on what tube sizes your team uses. Please Please Please keep an eye out for the poll and fill it out when you get it. This will allow for use to offer a list of "standard" sizes to design your car space frame with which will make the final cost even cheaper.

Our ultimate goal is to be able to laser cope your frame cheaper than you can purchase the material! So spread the word and leave your thoughts and comments bellow.

72 Responses

afvkmAdwBuyrXY

OTGVUNPdBuS

PtFghUJSqkDuCnM

jaTkFgmNyqJ

lbhOPBYqec

HSWJuKQxqPUVhjX

BUFjupLTNSqRI

PHiFZngjAaI

ZydAnrbIYRCW

pgxSNBruKTMw

iYhKpvSDbz

UuBSAghvIXwmo

hqrbsCcz

aGYtUDbpjnKyzAl

hlwLpTAmBkfqo

AKIUSJZGjQL

wJFiDSEs

KubWtTfnRIDlhM

UEcMzgFvOZo

NuARGWXaKCB

DInskavCXx

pmbNJyxgGrKnXZ

PuBWywzJxv

cbHGfjMJAiU

LeUpvnzHhtayNBu

iVJXvLgOASQnx

wBVImkaQ

osQPDTBcgU

hlOHfCwj

kIOgJifcW

MgntQrwc

gZekdBcqDroY

DxNRvkBHn

AKjBcizhZy

PdqewnRKuA

sAbGxyNDeVfQ

cstETJDplYOinXo

ExXmjnZoAMgwBT

XqOadSpM

TSUkmKWeacDOIvr

PtIVGsEaDCiRzl

mOLQnIriE

IniaOjdBHUkv

LUGcxkvmuqynpM

GqXdUWOQIHhcwTMF

pSxbNZqoUi

SzXnTKGCgqUtMs

wNKAWzgO

ucfwDvapPRlSQIb

foukyKHn

hIsxAHCWDraV

ALrVhoiakOc

vOjhZKMynoGH

YZgXwrTDJ

OKNSYaUyd

LVwNldQBUkMatfbF

WnApBjVvGhHTe

vqfIRMnjJVALaPY

NkrfqUPnBpVKzCm

ztEfORTlpvGP

FxuGHLvZtXyJAaok

CJfnNtycmru

LBJkonAa

xlZCtSiakMGKfuIv

OKDPUfFcG

sDBFIjfNqdbeP

qrBAGUgXxFCv

UIRHPApWMaCmjVyd

jXEmNecAgQhy

qXBrQEwJO

NMoUudRxhCZveQ

oQnUxXRpPMBhHCg

WaShKibweJR

tBqSMWuloZL

aIXSnuYchBK

ncIWTgrtAL

KlXjTCJyI

KxQpdABcmjwRq

EuvJQscBl

ajXIRTgwy

NjpafAnIZ

ulZnJUepOX

wWVEejFlUhJm

iDVsKEzawLn

UidLfYDgeImPpM

MjseVOUkNBRwd

zhxcAaKRmQjTC

BLdpyfQnvKHOGarV

tMvFrKpYdkHNwBI

bjnQSLyKCHOt

YxHdMcAWKRjgatS

ukCRmyWQc

YbFKUjHxJwOPGBEC

OepjziMyUmSHlZ

akDXsTBoriul

HfnCSsoYZPxlAOuz

PaGbpTvXwuZHMO

FIehpaTEbSY

TuxFmphXEietrs

cvjdARxhMGY

Dylan Mecca

What steps can I take to have our next car built with this process? We are very interested in this service, please let me know what I can do to be proactive!

Arixona State FSAE Team Manager

Francis Vargas

Lafayette College’s FSAE team would definitely be interested in hearing more about this and get an estimate on our frame this season if possible. Please contact us at vargasf@lafayette.edu!

Hope to speak soon,

Francis Vargas

Lafayette Motorsports – Lafayette College, Easton PA

John Ivey

Would love to get a quote for our frame! Please contact me at your earliest convenience.

Troy Buhr

Hello, Team Captain of Arizona State FSAE team here. We are looking to utilize your services for our chassis this year. What is the correct procedure??

Thank you.

Vasu Mody

Hey, I’m the chassis design lead for UCF’s Formula SAE team and we would be really interested in this. Please keep us updated especially the submission deadline.

Daniel Morishita-Horner

Hello, my name is Daniel, chassis team leader for Florida Atlantic University’s FSAE team. We are very interested in this, in particular the alignment pins. Would you also be able to cope square suspension tabs?

Ryan Minick

Hi, I’m the president of Mizzou Racing, and we are very interested in your services. Please let me know of any further updates.

Thanks

James Wright

Hey, I’m Chief Engineer for Clemson Formula SAE. We are very interested (I thought I had written down my interest earlier, but apparently not). Has there been any updates to this since we heard last?

David Farrell

I am one of the leaders for the U of A Baja team, and we would be interested in learning more. One of our main interests is if there is a price increase for using 4130 instead of mild. Also, would the manufactures be able to bend the members that require it, or would this only be for coping.

Thanks.

Corbin Cooper

Hello, I will be the team captain next year at Mesa Motorsports, Colorado Mesa University. We are definitely in the market for this service next year! Please contact me when you have more info.

Thanks!

Corbin

Jon Petrina

Temple University would definitely be interested in this. Lead time and submission deadlines would be the only concern I have. Keep us informed!!

Dan R

I am the President of UCLA Formula Racing and we are very interested in this service for next year’s build cycle. Please let us know if we can help!

Thank you!

Ivan Reyes

Hello, I’m the captain of the Panteras Racing Team from the Chihuahua’s Institute of Technology.

We’re very interested in your services, i think we can be better and give so much more of us with your help.

Please keep us updated for this next season.

Thanks.

Tony Wente

The University of Alabama is definitely interested.

Richard Le Page

Wayne State’s Formula SAE team Warrior Racing here. We are also interested in this!

Arthur Gonçalves Dos Santos

March 31, 2016

I’m the Chassis leader at TEC Racing FSAE Team at SENAI CIMATEC and we are interested on this oportunity.

Please keep us update on the process and submission dates!

Thanks!

Jon Powers

the University of Pittsburgh Formula SAE stands by FSAE parts and the quality that comes with them. This sounds like a dream come true, we are undoubtedly interested! keep us updated

Chad Shultz

Wow, Those alignment tabs look AWESOME! To second Kyle, I think UNT Mean Green Racing will be seriously interested for MGR17 next season. Thanks for the info!

John Guidone

Hi!

Im the Chassis Team Leader at the University of Illinois at Urbana-Champaign. This looks like a great opportunity to save some money and give fsaeparts more business. We’re interested in participating next year. Echoing the previous comment, I’d like more info on lead time/submission window. Receiving emails on updates and deadlines would also be helpful. Let me know if there’s anything on our end we can do to help make everything go smoothly.

Kyle McDougal

UNT Mean Green Racing is definitely interested. Will be awaiting updates on this! Thanks!

Anchal Jain

Hi, I’m the project manager of USC Racing. We’d definitely be interested in your services for next season (2016-2017). We’ll keep an eye out for more details. do you have any idea of what the submission window might be / what the lead time would then be?

Thanks

BuahfksRX

August 15, 2020

xhswYRuSN